ComStar International

What

• Flooded Chiller Conversion

• Refrigerant Management

• Refrigerant Management

Who

Chemical Plant

Where

Houston, Texas

Flooded Chiller Conversion: From RS-22 to RS-45 (R434A)

ComStar International chose Star Service of Houston and New Orleans as the General Contractor, and specifically Star Service's Brian Keating, as the Project Manager to perform a Flooded Chiller Conversion with the assistance of Advanced Refrigerant Technologies of League, Texas.

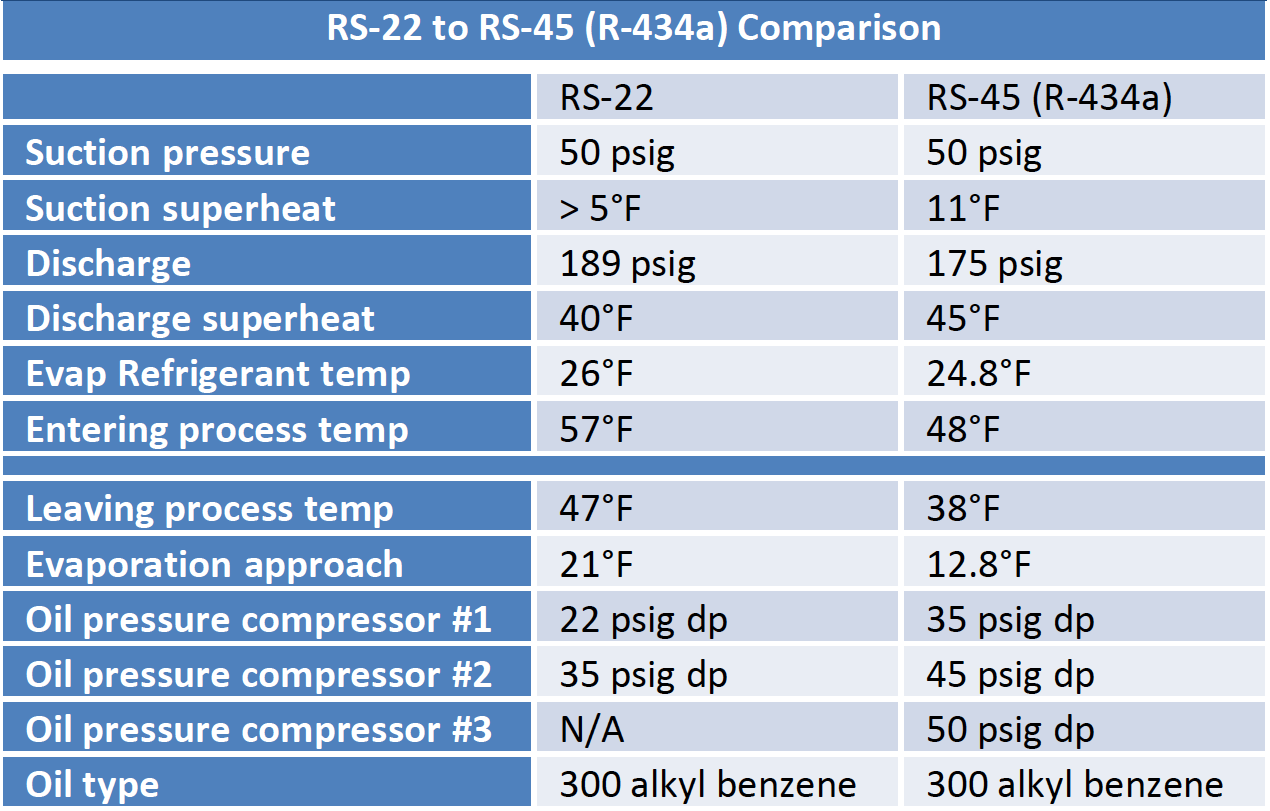

The process involved converting an RS-22 Flooded Chiller system to the unique match capacity of an RS-45 (R434A).

The process involved converting an RS-22 Flooded Chiller system to the unique match capacity of an RS-45 (R434A).

Specifications

- 3 Carrier SH80 Compressors driven by 75 HP motors in direct drive, tandem configuration

- Utilizes independent discharge oil separators

- Shares common discharge and suction with check valves on the discharge line

- Oil system utilizes a typical oil skimmer line configuration, skimmed off of the evaporator at 60% desired liquid flooded level

- Utilizes a suction surge drum to promote liquid-free suction gas

- Refrigerant/oil mixture is delivered to a batch oil pot, is heated to 120°F. Oil is then pressurized by discharge oil separator gas and superheated refrigerant pressure

- RS-22 refrigerant change of approximately 3,000 lbs.

- Utilized alkylbenzene 300 oil

Preparation

- Removed approximately 3,000 lbs. of RS-22 refrigerant and alkylbenzene 300 oil

- Serviced two of three compressors and changed out several critical system components

- Performed leak checks

- Performed vacuum/dehydration process, pulled system to depth of 2mm HG until a depth of 1.5mm HG was achieved. Holding period of six hours at a minimal rise of 100 microns

- Charged system with 2,000 lbs. of RS-45